When it comes to unleashing the power of polyethylene foam, the possibilities are endless. This versatile material has found its way into numerous industries, offering a wide range of applications that showcase its unique properties and benefits.

- Polyethylene foam is lightweight, making it ideal for applications where weight is a concern.

- Its excellent cushioning properties provide superior protection for fragile items during transportation.

- The material’s resistance to water and chemicals ensures durability in various environments.

With these characteristics, polyethylene foam has become a game-changer in industries such as packaging, insulation, sports equipment, and automotive components. Its impact is felt across different sectors, revolutionizing the way products are protected and transported.

Let’s delve deeper into the world of polyethylene foam and uncover the endless possibilities it offers for innovation and advancement. From enhancing safety in packaging to promoting sustainability, this remarkable material continues to surprise and impress with its unmatched capabilities.

Properties of Polyethylene Foam

Polyethylene foam is a remarkable material known for its exceptional properties that make it highly versatile and valuable in various industries. One of the key characteristics of polyethylene foam is its lightweight nature, which makes it easy to handle and transport. This feature is particularly advantageous in applications where weight is a critical factor.

Another significant property of polyethylene foam is its excellent cushioning properties. This foam material provides superior protection against impacts and shocks, making it ideal for packaging delicate items or for use in sports equipment where impact absorption is crucial.

In addition to its cushioning capabilities, polyethylene foam is also resistant to water and chemicals. This resistance makes it suitable for applications where exposure to moisture or chemicals is a concern, ensuring the durability and longevity of the foam in various environments.

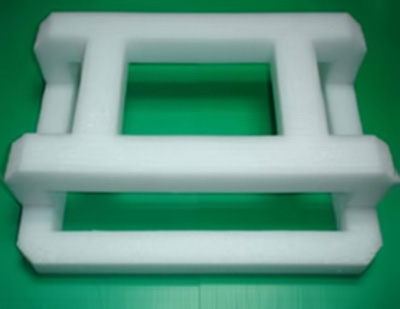

When considering the properties of polyethylene foam, its flexibility is worth mentioning. This material can be easily manipulated and shaped to fit specific requirements, allowing for customized solutions in different industries. Whether it’s creating protective packaging inserts or insulation for automotive components, the flexibility of polyethylene foam offers endless possibilities.

Moreover, polyethylene foam is durable and long-lasting, providing reliable performance over time. Its resilience to wear and tear ensures that products made from polyethylene foam maintain their integrity and functionality even after prolonged use.

Overall, the properties of polyethylene foam, including its lightweight nature, excellent cushioning properties, resistance to water and chemicals, flexibility, and durability, make it a standout material with a wide range of applications across industries.

Applications in Packaging

When it comes to applications in packaging, polyethylene foam stands out as a game-changer in the industry. Its superior protective qualities have revolutionized the way fragile items and electronics are transported and stored. The lightweight nature of polyethylene foam makes it ideal for packaging delicate products without adding unnecessary weight.

Polyethylene foam’s excellent cushioning properties provide a reliable barrier against impact and pressure, ensuring that items remain safe and intact during transit. Whether it’s glassware, electronics, or sensitive equipment, polyethylene foam offers a level of protection that is unmatched by traditional packaging materials.

One of the key advantages of using polyethylene foam in packaging is its resistance to water and chemicals. This feature makes it an ideal choice for products that require protection from moisture or corrosive substances. By creating a barrier between the external environment and the packaged item, polyethylene foam ensures that goods arrive at their destination in pristine condition.

In addition to its protective qualities, polyethylene foam is also versatile and customizable to suit various packaging needs. It can be easily molded and shaped to fit specific products, providing a tailored solution for different industries. From custom inserts for electronic devices to cushioning for delicate glassware, polyethylene foam offers a flexible packaging solution that adapts to diverse requirements.

Environmental Sustainability

When it comes to environmental sustainability, polyethylene foam stands out as a champion in the materials world. Its eco-friendly attributes make it a top choice for industries aiming to reduce their carbon footprint and promote green practices. Let’s delve into the key aspects that highlight the environmental sustainability of polyethylene foam:

- Recyclability: One of the most significant advantages of polyethylene foam is its recyclability. This material can be easily recycled and reused in various applications, reducing waste and promoting a circular economy.

- Energy Efficiency: In the production process, polyethylene foam requires relatively low energy consumption compared to other materials. This energy efficiency aspect contributes to overall sustainability efforts.

- Reducing Carbon Footprint: By choosing polyethylene foam for packaging, insulation, or other applications, companies can actively contribute to reducing their carbon footprint. The lightweight nature of polyethylene foam also helps in lowering transportation emissions.

- Durability and Longevity: Polyethylene foam’s durability ensures that products made with this material have a longer lifespan, reducing the need for frequent replacements and ultimately decreasing waste generation.

Furthermore, the versatility of polyethylene foam allows it to be used in various industries without compromising its environmental sustainability. Whether it’s protecting fragile items during shipping or providing insulation in buildings, polyethylene foam proves to be a reliable and eco-conscious choice.

While coming to the end of our article, do not forget to review the following service pages of Durfoam: