Before we start our article, we strongly recommend that you review Durfoam‘s product pages below:

PE foam, also known as polyethylene foam, is a versatile material that serves as the key to lightweight packaging solutions. This type of foam is renowned for its exceptional properties that make it an ideal choice for various packaging applications. From providing cushioning and protection to being lightweight and eco-friendly, PE foam stands out as a top contender in the packaging industry.

What is PE Foam?

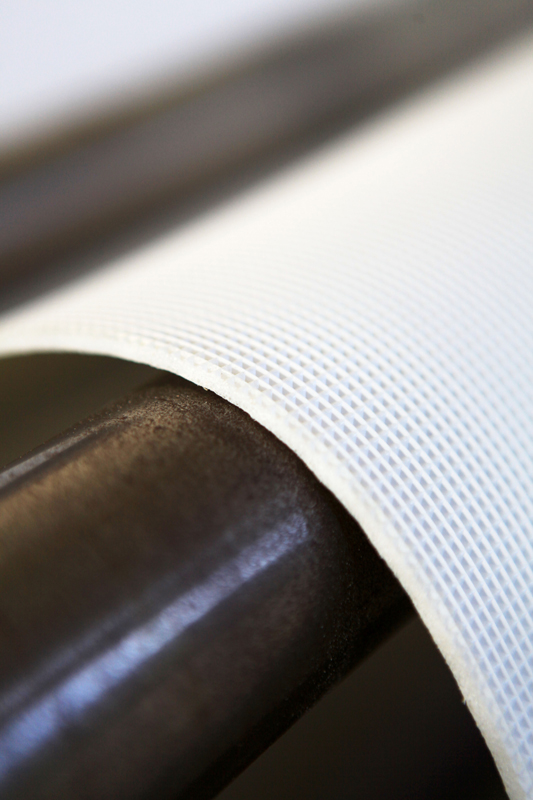

PE foam, also known as polyethylene foam, is a versatile material widely used in the packaging industry due to its lightweight and protective properties. This type of foam is made from polyethylene, a type of plastic known for its durability and flexibility. PE foam is characterized by its closed-cell structure, which provides excellent cushioning and shock absorption capabilities. It is commonly used to protect fragile items during shipping and handling, preventing damage from impact and vibrations.

One of the key features of PE foam is its lightweight nature, making it an ideal choice for packaging applications where weight is a concern. Despite being lightweight, PE foam is incredibly resilient and can withstand heavy loads without losing its shape or protective qualities. This makes it a cost-effective solution for companies looking to reduce shipping costs while ensuring the safety of their products.

PE foam is a popular choice for packaging due to its versatility and ease of customization. It can be easily cut, shaped, and molded to fit specific packaging requirements, providing a tailored solution for various products. Whether used as protective inserts in boxes or as wrapping material, PE foam offers flexibility in design and application.

Additionally, PE foam is environmentally friendly, as it is recyclable and reusable. This makes it a sustainable packaging option for companies looking to reduce their carbon footprint and minimize waste. By choosing PE foam for packaging needs, businesses can demonstrate their commitment to eco-friendly practices and responsible packaging solutions.

Benefits of Using PE Foam

When it comes to packaging solutions, PE foam stands out as a versatile and reliable material. Its benefits go beyond just providing protection for your products. Let’s delve into the advantages of using PE foam for packaging:

1. Cushioning Abilities: The soft and pliable nature of PE foam allows it to conform to the shape of the product, providing excellent cushioning and shock absorption during transit. This feature ensures that your items reach their destination intact and undamaged.

2. Versatility: PE foam can be easily customized to fit various shapes and sizes, making it suitable for a wide range of products. Whether you are shipping fragile electronics or delicate glassware, PE foam can be tailored to meet your specific packaging needs.

3. Eco-Friendly Attributes: In today’s environmentally conscious world, sustainability is key. PE foam is a recyclable material, reducing the environmental impact of your packaging. By choosing PE foam, you are not only protecting your products but also the planet.

Moreover, the lightweight nature of PE foam helps in reducing shipping costs and carbon footprint. Its ability to provide reliable protection while being environmentally friendly makes it a top choice for businesses looking to balance efficiency and sustainability in their packaging solutions.

Applications of PE Foam in Packaging

PE foam, with its versatile and lightweight properties, finds a wide range of applications in the packaging industry. One of the primary uses of PE foam in packaging is for protecting fragile items during transportation and storage. The cushioning abilities of PE foam make it an ideal choice for safeguarding delicate products such as electronics, glassware, and ceramics from damage due to impact or vibration.

In addition to protecting fragile items, PE foam is also utilized in the food and beverage industry for insulating perishable goods. Its thermal insulation properties help maintain the temperature of food items, ensuring freshness and quality during transit. From hot meals to cold beverages, PE foam packaging plays a crucial role in preserving the integrity of food products.

Furthermore, the automotive industry benefits from the use of PE foam in packaging components and parts. The lightweight nature of PE foam helps reduce overall packaging weight, leading to cost savings in transportation. Additionally, PE foam’s shock-absorbing properties protect automotive parts from damage, ensuring they reach their destination in pristine condition.

PE foam is also extensively used in the healthcare sector for packaging medical devices, equipment, and pharmaceutical products. Its non-abrasive surface and ability to conform to various shapes make it an excellent choice for ensuring the safe delivery of sensitive medical supplies. Whether it’s surgical instruments or diagnostic tools, PE foam packaging provides a reliable protective barrier.

Future Trends in PE Foam Packaging

As we look ahead to the future of PE foam packaging, it’s clear that exciting trends and innovations are on the horizon. One key trend that is gaining momentum is the focus on sustainability. Manufacturers and consumers alike are becoming more environmentally conscious, leading to a demand for sustainable packaging solutions. PE foam, with its lightweight nature and recyclable properties, is well-positioned to meet this growing need for eco-friendly packaging materials.

Furthermore, efficiency improvements are shaping the future of PE foam packaging. Innovations in manufacturing processes and materials are allowing for greater efficiency in production, leading to cost savings and reduced waste. These advancements not only benefit the companies utilizing PE foam but also contribute to a more sustainable and streamlined packaging industry as a whole.

Another trend to watch in the world of PE foam packaging is the increasing focus on customization and personalization. With advancements in technology, manufacturers can now tailor PE foam packaging to meet specific customer needs and preferences. Whether it’s creating unique shapes, sizes, or designs, customization offers a level of flexibility and creativity that was previously unmatched in the packaging industry.

Moreover, the integration of smart packaging technologies is set to revolutionize the way PE foam is used for packaging purposes. From intelligent tracking systems to interactive packaging solutions, the future of PE foam packaging is becoming increasingly interconnected and data-driven. These innovations not only enhance the functionality of PE foam but also provide valuable insights for both businesses and consumers.